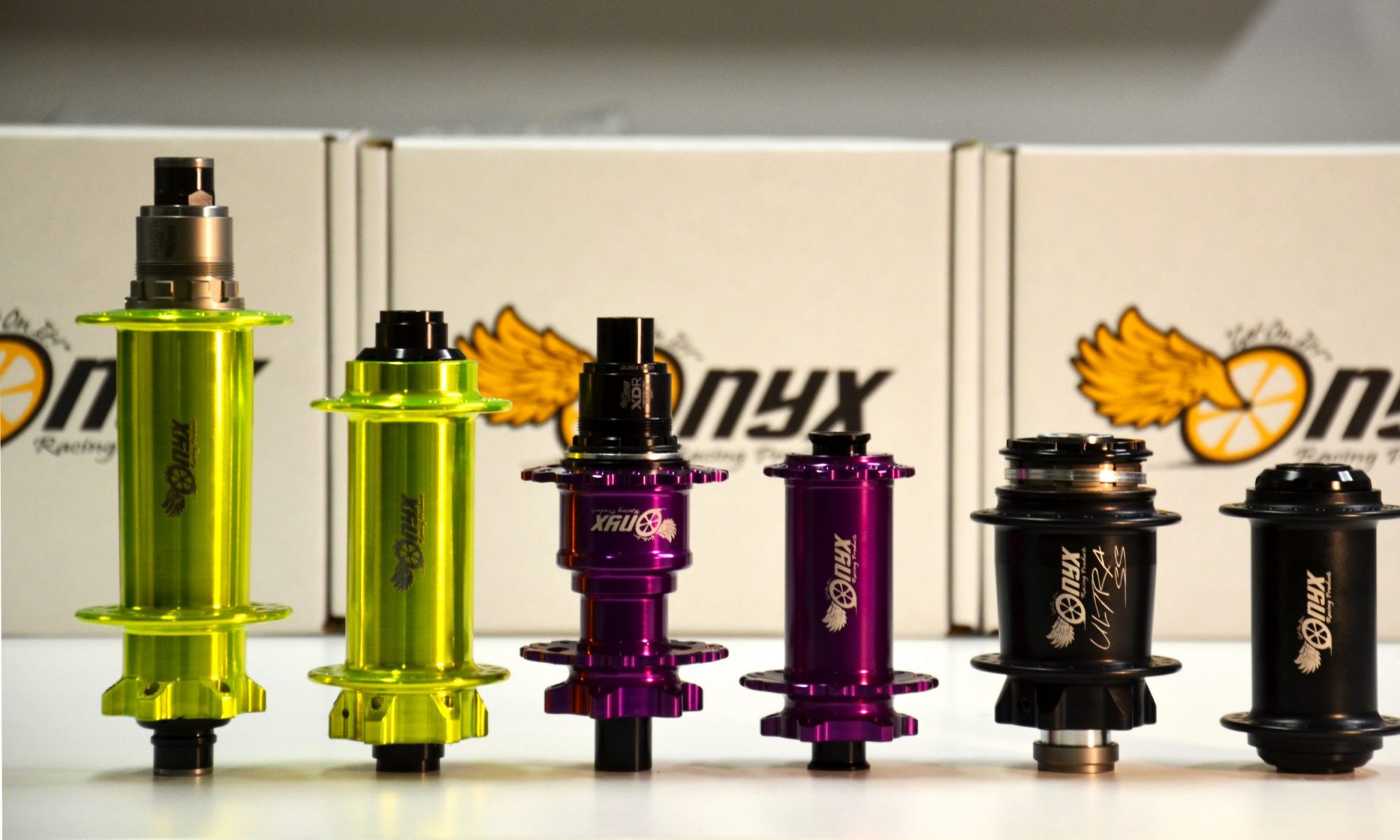

Bearings are what keep hubs running smoothly – and among almost innumerable other applications, bicycle-related or not. Onyx Racing Products hubs are one, if not with the lowest friction and therefore drag out there. The types of bearings used have a big role in this much-desired feature. Therefore a more detailed look is well-warranted.

Bearing Types

Bearings come in various sizes and shapes. As is often the case, the trick is to choose the one that fit the intended purpose and the demands posed by it as well as possible. To limit the area covered here, the discussion is only about cartridge bearings which are (nearly) the industry standard in all high-end hubs.

Some of the benefits that come with cartridge bearings include the following:

- Available in a variety of sizes.

- Ability to withstand very high loads when proper bearing size is used.

- A broad selection of types when it comes to materials, the level of sealing & protection needed.

- Easily replaceable.

- Durable and long-lasting when installed and maintained properly – assuming the design is sound to start with.

In short, cartridge bearings are the winning choice for bicycle hubs, and in almost all bicycle-related components. Other bearing types include things like roller/needle bearings, tapered roller bearings, angular contact bearings etc.

When the discussion is about high-quality bearings, the topic of ceramic bearings often comes about. This refers to the material used to build the bearing. Commonly, three types of bearings are used when it comes to material choice:

- Steel bearings – the balls and bearing races are made of high-quality steel.

- Ceramic bearings – the balls and races are made of very hard ceramic material, such as silicon nitride.

- Hybrid ceramic bearings – the balls are made of ceramic material, but steel is used in bearing races. The goal is to combine the best sides of both material types.

Bearing types 1. and 2. are used in Onyx Racing Hubs. More about this a bit later.

Bearings Size

One very important, but oftentimes overlooked aspect of bearings is bearing size. The bigger the bearing, the bigger the balls found in the (cartridge) bearing are. More size means more surface contact area and more mass. Even a slight increase in bearing diameter can bring drastic improvement in bearing ball size, the load rating, and oftentimes in durability. Besides bearing size, bearing placement has a big role how bearings can meet the demands they’re subjected to. The wider the bearings can be placed in the hub, meaning the more distance there is between them, the better it generally is for bor bearing performance and expected lifespan.

In short, saving on bearing size – for weight-saving reasons, for example – rarely pays off. Assuming that one does not find replacing bearings a particularly enjoyable activity.

All Onyx Racing Products hubs are equipped with proper size bearings. In practical terms, this means that the bearings are dimensioned to meet the loads they’re going to see in normal use. Onyx Racing Products hubs employ an assortment of 6902, 6804, 6805, 6806 and 6807 bearings, depending on the hub model and therefore the use it is normally subjected to.

What You Will Find in Onyx Hubs

As said previously, Onyx Racing Products hubs employ two types of bearings, depending on the hub model and possible upgrade options: steel bearings and hybrid ceramic bearings.

Hybrid ceramic bearings employ ceramic balls that are very hard, but also have an especially high “roundness factor”. Simply, ceramic balls can be made more round than steel balls. This in turn translates to bearings that run smoother and often times longer. The hybrid ceramic bearings used in Onyx Classic and BMX hubs, with the exception of OHM series, are manufactured by Verinent Bearings LLC – a well-known and highly reputable bearing manufacturer from the US.

Vesper hubs are assembled with high-quality steel bearings. However, a hybrid ceramic bearing upgrade option is available to anyone who wants to make the most of the Vesper hubs right from the start. For the OHM hubs, a separate Racing Spec upgrade option exists which includes titanium bolts beside the hybrid ceramic bearing option.

Maximizing Bearing Life

When running state-of-the-art bearings, it is worth touching on a couple of points on how to make the most of them and what are the best practices to get the most mileage out of them. The list of actions and considerations includes the following:

- Proper preload! The importance of the correct amount of bearing preload can’t be overstated. Cartridge bearings are capable of carrying considerable radial loads. The same does not apply to axial loads, however. Running too much preload puts an excessive axial load on the bearing, stressing it continuously and thus wearing it out prematurely. The correct amount of preload is the point where there’s no play – no more, no less. Onyx Racing Products YouTube Channel makes an excellent job in instructing preload settings and common service procedures. YouTube.com/OnyxRP

- Keep your bike clean. A clean bike is a nice bike to look at and use. Do not let dirt and other contaminants make their way to the delicate parts, such as bearings. On the other hand, excessive washing when it comes to frequency or amount of water and/or other chemicals used can be just as bad or even worse. When possible, cleaning the bike with just a rag is a good idea, and not to bring the water hose out unless needed.

- Do not use a jet washer for washing. The pressure that modern washers put out will push dirt and other contaminants past the bearing seals if not used with utmost care. In general, directing water spray directly to bearings is not recommended.

In Closing

If you’re choosing the Classic or almost any BMX hub from the Onyx Racing Products lineup (with the exception of OHM), you get to enjoy the benefits of state-of-the-art hybrid ceramic bearings. For Vesper hubs, this bearing choice is offered as an upgrade option.

Bearings are available as spare parts in the Spares & Components section.