The long-awaited Hook Flange versions of the Onyx Racing Products Vesper hubs are finally out! These hubs are developed specifically for Berd Spokes that are made of the super-tough polymer compound. Combined with the sprag clutch design found only in Onyx Racing Products hubs, this technology will create the ultimate wheelset!

Read further to learn more!

Berd Spokes

The first and obvious place to start is to introduce Berd Spokes and the technology behind it. Berd Spokes is a company hailing from the state of Minnesota in the United States. Their promise is none less than the following:

World’s lightest bicycle spokes. Experience the new state-of-the-art technology making steel spokes obsolete

-Berd Spokes

At the heart of the innovative technology is a polymer-derived material called ultra-high molecular weight polyethylene (UHMWPE). It has 12 times the strength-to-weight ratio compared to steel. It also has a significantly improved fatigue life and will not degrade from UV exposure. A nice-to-know fact: UHMWPE also floats on water.

In short, Berd Spokes are “polymer strings” with an embedded and threaded steel end that acts as the contact point between the spoke and the nipple – just as in traditional spokes.

Besides being super-lightweight, Berd Spokes offer some unique advantages that can’t be achieved with traditional steel spokes.

- Lightweight wheels! The use of Berd Spokes can save up to 200g per wheel, depending on the build.

- Vibration damping. The UHMWPE material damps vibrations in a way that steel spokes can’t.

- Improve compliance – on a significant scale. Because of the specific spoke tension used on Berd Spokes in addition to the unique material properties, wheels built with Berd Spokes provide a compliant, but still sharp ride feel!

For more information, please see the technical Q&A section at berdspokes.com

The Hook Flange Design

The innovative Hook Flange design is the result of collaborative work between Onyx Racing Products and Berd Spokes. The goal of the eye-catching flange design is to make the build and service procedures an order of magnitude easier and faster compared to traditional hub flanges designed for J-bend (or straight pull) spokes.

Näytä tämä julkaisu Instagramissa

With traditional hub flanges, the spoke holes need careful preparation before the build. This includes rounding the spoke holes so that the sharp edges do not cut the spoke material or cause any unwanted stress risers.

In addition to that, the installation of the spokes is more time-consuming compared to traditional steel spokes. The Hook Flange design eliminates these two factors entirely.

The Benefits

Since we are talking about new and ground-breaking technology, it’s best to summarize the benefits that are on offer.

- Significant weight savings compared to traditional steel spokes.

- Vastly improved ride quality, thanks to the compliant nature of the build made with Berd Spokes.

- A high degree of durability. The UHMWPE material used in Ber Spokes is very strong and tough, making breakages highly unlikely.

- Ease of installation and maintenance!

- Instant engagement, silent operation and minimal drag – all standard features Onyx Racing Products hubs are known for.

Lacing considerations

Berd Spokes released a very informative instructional video that covers important information regarding lacing patterns and how they relate to spoke hole count. Combined, these two pieces of information have a critical effect on spoke length calculation!

| Spoke Hole Count | Lacing Pattern |

| 24 | 2-cross |

| 28, 32 and 36 | 3-cross |

Refer to the video on how the spokes are installed and to see how they cross each other.

Availability

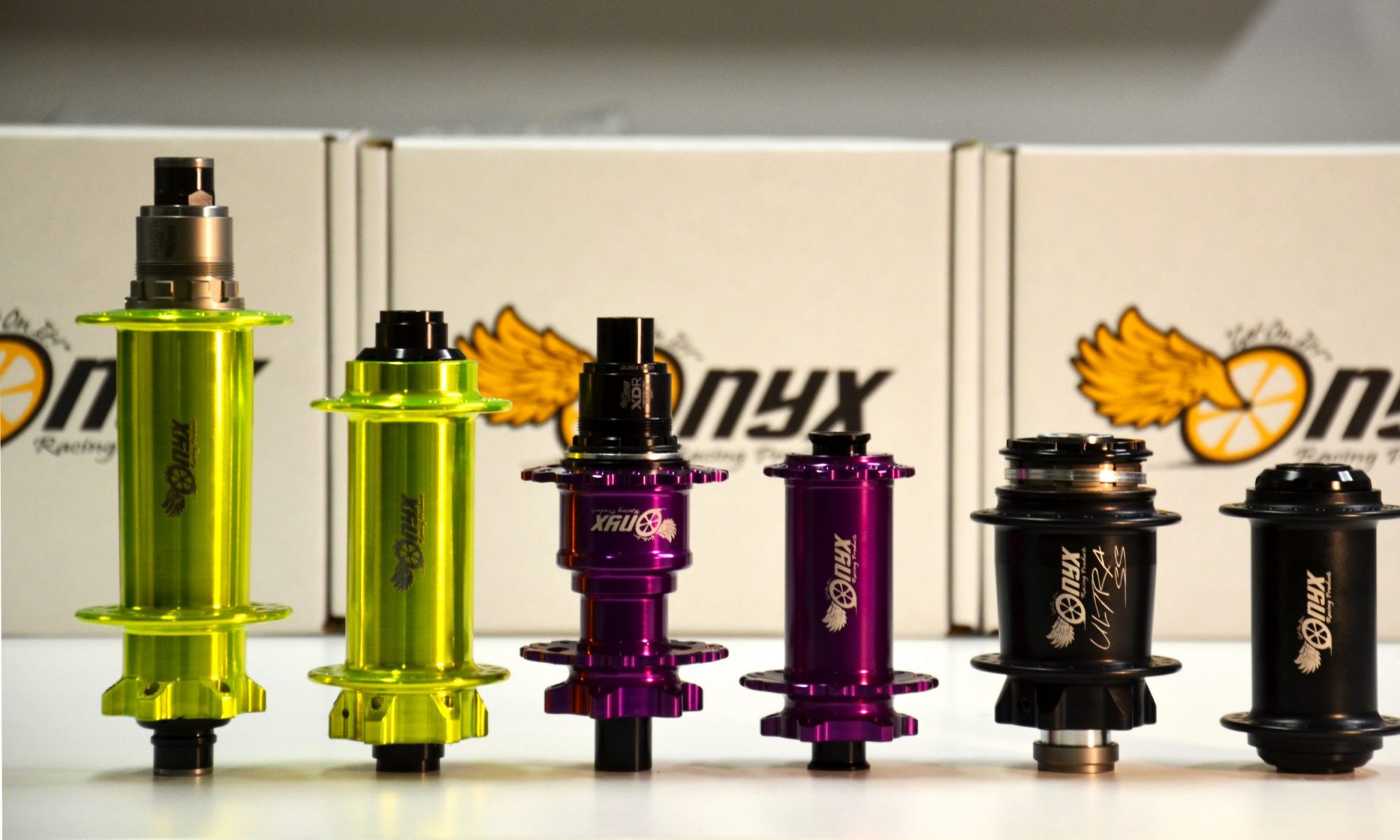

The Hook Flange design will be available in Vesper hubs, the lightweight version in the Onyx Racing Products lineup that’s geared towards XC, trail riding, gravel and road. The list of available axle spacing and spoke hole count options includes the following.

| Axle Spacing | Spoke Hole Count | Disc Mount | |

| Front | Quick release | 24 or 28 | Centerlock |

| 100x12mm | 24 or 28 | Centerlock | |

| 100x15mm | 24 or 28 | Centerlock | |

| 110x15mm (Boost) | 28 or 32 | Centerlock | |

| 110x20mm | 28 or 32 | Centerlock | |

| 100x10mm Bolt-on or 100x20mm (BMX) | 36 | – | |

| 150x15mm FAT | 32 | Centerlock | |

| Rear | Quick release | 24, 28 or 32 | Centerlock |

| 142x12mm | 24 or 28 | Centerlock | |

| 135x10mm HGSS Bolt-on & 142x12mm HGSS (Single-speed) | 28 or 32 | Centerlock | |

| 148x12mm (Boost) | 28 or 32 | Centerlock | |

| 157x12mm (Super Boost) | 28 or 32 | Centerlock | |

| 177x12mm & 197x12mm FAT | 32 | Centerlock | |

| 110×10 mm Bolt-on, 110×12 mm or 110×15 mm Thru-bolt | 36 | ISO 6-bolt |

Get in touch to build the ultimate wheelset! In addition to Onyx Racing Products hubs, we are able to supply Berd Spokes and the required build kits to take the wheel build from start to finish.

info(at)onyxhubseurope.com

Updated on 14.12.2022 with lacing instructions provided by Berd Spokes.