The sprag clutch mechanism is the secret behind the awarded instant and silent engagement in Onyx Racing Products hubs. Here you can learn what goes into this technology, and what advantages it brings to the table.

Rooted in Industrial Applications

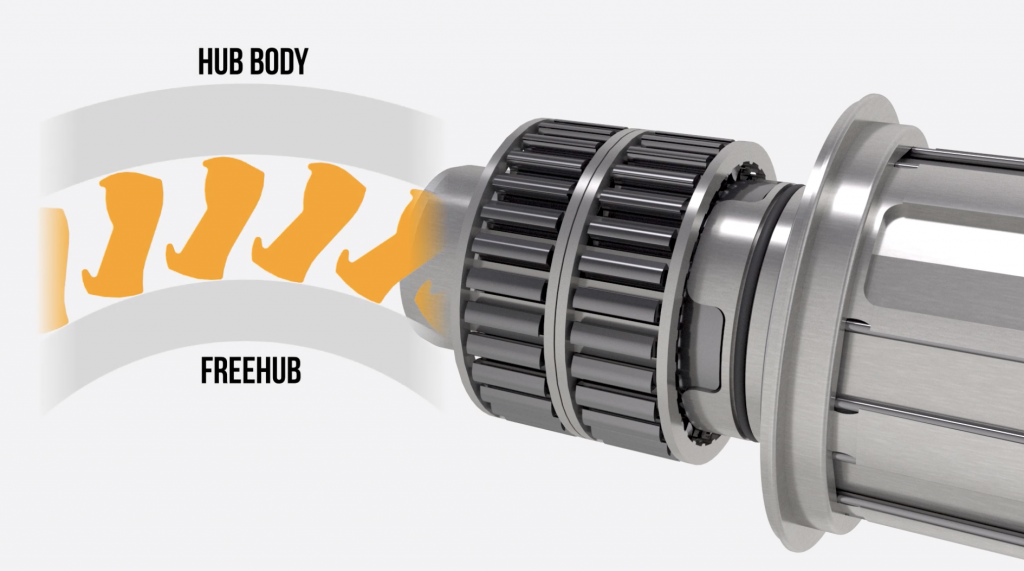

The sprag clutch mechanism resembles a roller bearing, with the key difference that instead of perfectly round balls, the sprags are shaped like an asymmetrical figure-eight. Another big difference is that the sprags do not rotate, but sit still between two rotating cylindrical surfaces.

When torque is applied to the system and the direction of rotation changes, the sprags wedge themselves between the two cylindrical surfaces and thus creating a very strong coupling based on friction.

See the sprag clutch in action on the photos below. On the left-hand side, the sprags are disengaged, allowing the hub body and the freehub to spin freely in relation to each other. On the right side photo, torque is applied to the freehub body via drivetrain and engagement has taken place.

Sprag clutch mechanism is widely used in industrial and automotive applications, as well as in aviation. If the sprag clutch mechanism is strong and reliable enough to transfer power to the rotor of a helicopter, it’s up for the task to transfer all the power available from one’s legs to the rear wheel.

The Benefits

That’s for the technical jargon.

“What’s in it for me?”

Glad that you asked. The sprag clutch mechanism offers several benefits, all of which can be felt on the trail, road or track. The most notable are listed below:

- Instant engagement. The sprag clutch mechanism offers instant engagement. In other words, when power is applied to the pedals, and thus torque to the rear hub, the system engages with zero delay! Gone are the days when you have nearly 1/4 of slack of the crank revolution before the rear hub picks up, making your bike feel almost like broken.

- Smooth pick up. The engagement of the sprag clutch mechanism isn’t binary in nature as in most other system found in the market. Conversely, there’s a wind up effect when the sprags “stand up” between the hub shell, and freehub, creating a softness in the engagement. Many riders feel that this adds grip which is beneficial especially on steep uphills. If this is of concern, and/or you want to learn more, head to our FAQ section.

- Silent operation. No sound is produced when the sprag clutch operates. In other words, you can ride in full stealth mode, and enjoy the sounds of the environment.

- Low-drag. Compared to other freewheel mechanisms, the sprag clutch system is one of the most, if not the most low-friction option out there. The sprags are in very light contact with the rotating surface, otherwise engagement would not happen when torque is applied, but the drag caused is among the lowest, if not the lowest among all hubs. Want to have hubs that spin silently and nearly indefinitelty? Choose Onyx Racing Products.

- Low-maintence. The sprag clutch mechanism or any other component of the Onyx Racing Products hub is not subjected to high wear rate, or do not use components like springs, that are subjected to wear or fatigue, and thus require frequent maintenance.

Video Instead?

Do you prefer video format instead? Then watch this excellent video made by Onyx Racing Products.

Photo credit: Onyx Racing Products